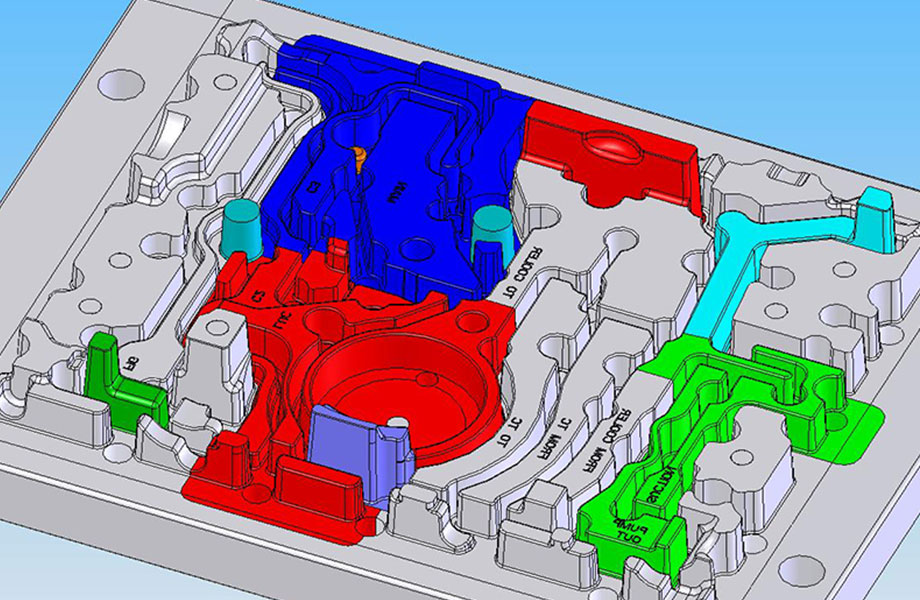

Low pressure die cast tooling

We design all the tooling for the low pressure process, Dies, Core Boxes, Machines & Fixtures.

This enables HCM to be the one stop solution for the complete cell to reduce lead times and cost. Any change requests during the design/developement is then optimised as all under one roof.

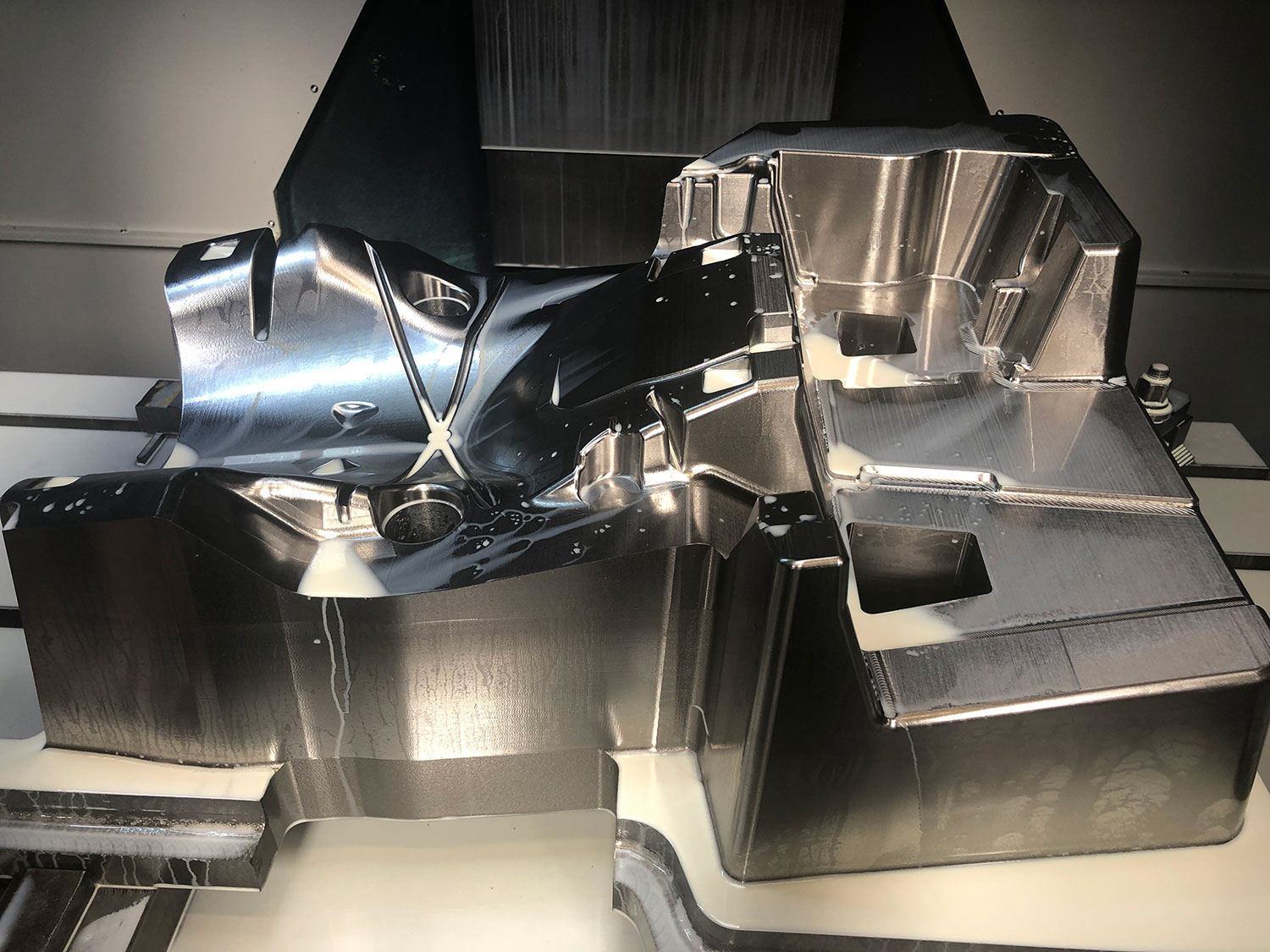

Low pressure sand core box equipment

The Low Pressure process enables the component to have complex internal cast shapes to form chambers. It could be oil galleries, water channels or pipe form so that a complete internal and external compoennt can be cast.

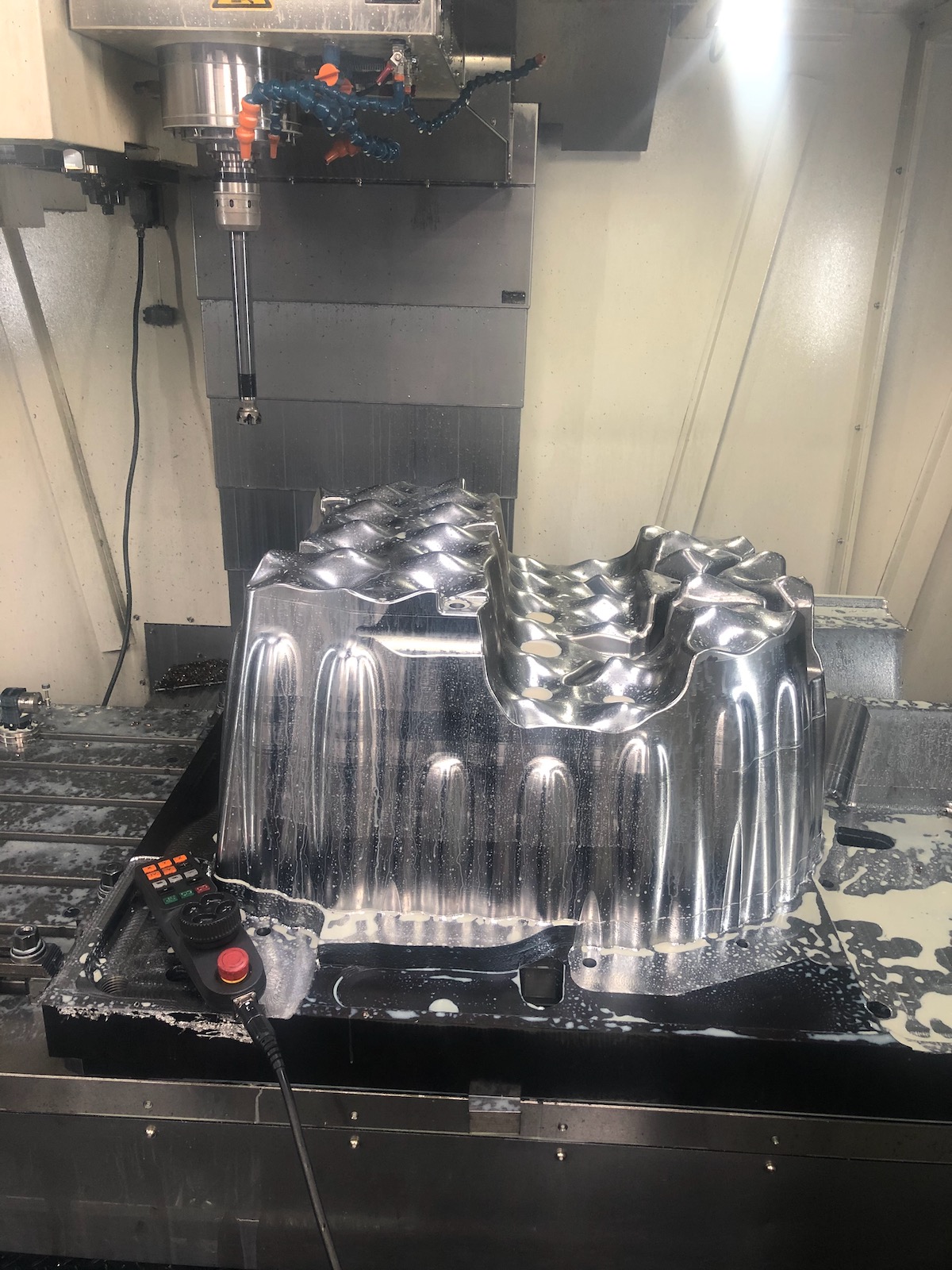

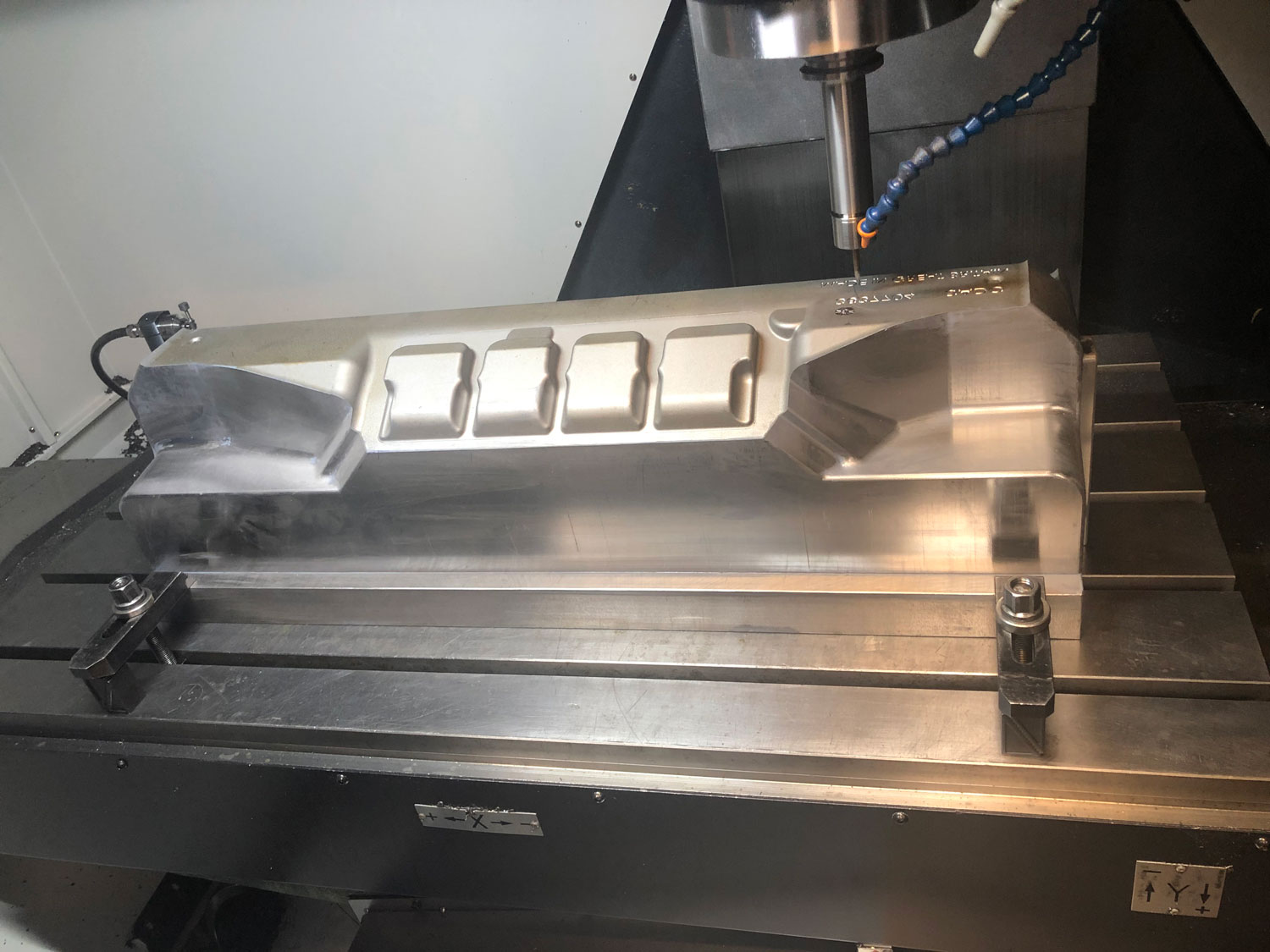

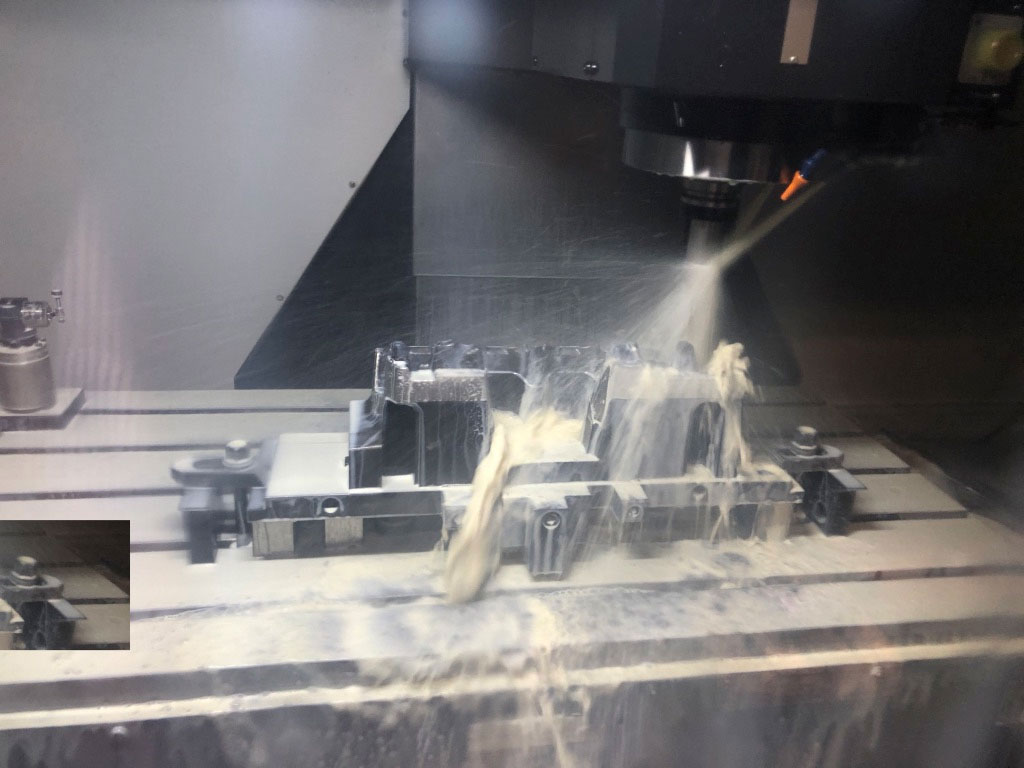

Large temperature controlled tooling

The mould filling properties of low pressure die casting make it suitable for thin-wall, large surface parts, with high yields as runners and riser are excluded.

With large tooling up to 3 metres in length the temperature control and thermal expansions have to be managed via temperature balanced tooling and sometimes straightening fixtures.